The PhD High-Pressure Homogenizer is powered by a versatile power source, adaptable to both 110V/380V and 60/50 Hz. It encompasses one or more plunger pumps that execute reciprocating movements, allowing the material to access an adjustable pressure valve assembly. Consequently, the material navigates through specially designed throttling slots in the homogenization zone. Here, it undergoes a swift pressure reduction and is propelled out at remarkable speeds, between 1000-1500 meters per second.

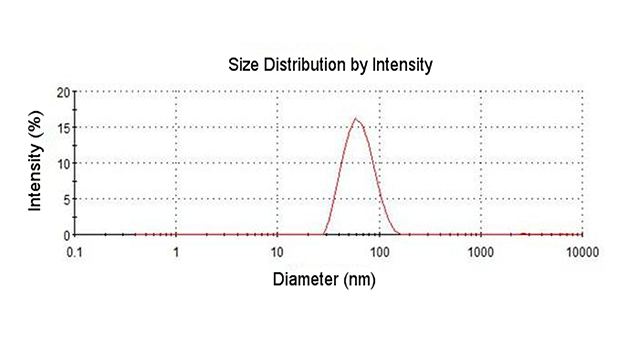

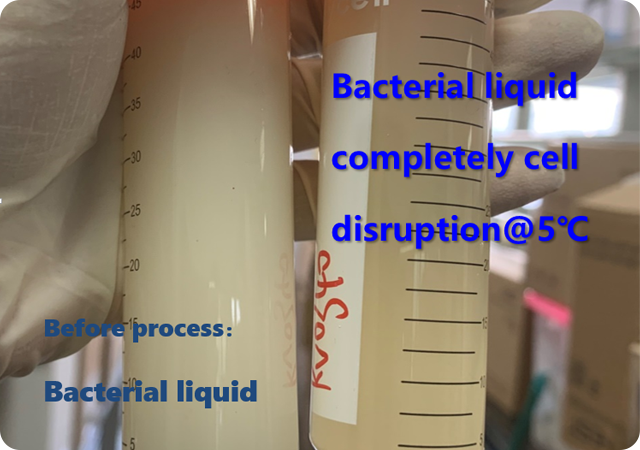

Inside this homogenization valve, the material experiences three principal effects: cavitation, impact, and shear. These effects not only collaborate to process the material efficiently but are also integral for achieving optimal refinement. They ensure the material is processed to the highest quality and consistency, reducing particle size to below 100 nm and achieving a cell disruption rate of over 97%.

The high-pressure homogenizer facilitates emulsification, fluid dispersion, homogenization, and cell disruption for biological purposes. It is prominently used across industries like pharmaceuticals, biotechnology, life sciences, cosmetics, food, and fine chemicals. This equipment is especially preferred for facilitating cell lysis and developing liposomes, emulsions, and suspensions. Designed for both research and production, it’s ideal for laboratories, research institutions, and manufacturing settings compliant with GMP standards.